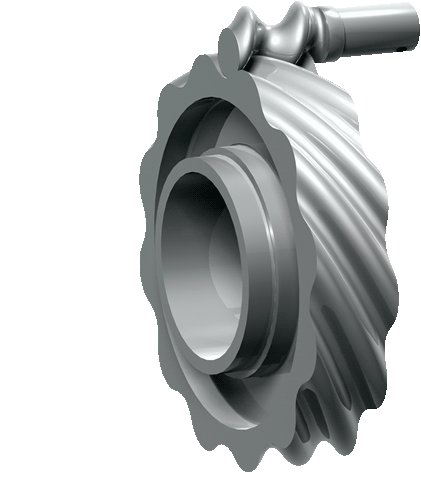

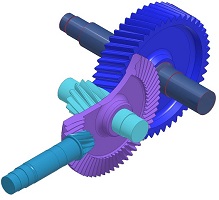

EC gearing, a new kind of toothed engagement — is a fundamental resource and energy saving development in the field of machine-building industry

A new kind of gearing called eccentrically cycloidal (EC) is developed,

on its basis the manufacture of almost any type of gearbox is possible

(cylindrical, planetary and bevel EC-gearboxes, and also

rack-type EC gears for mechanisms with rectilinear motion).

The new kind of gearing is asserted by 7 patents of Russian Federation.

International applications are filed.

![]() How it works

How it works

Publications

Publications

![]() Press about us

Press about us

Dissertations and discussions

Dissertations and discussions

EC-gearing presentation 2020

EC-gearing presentation 2020

Presentation of JSC "Technology Market" 2021

Presentation of JSC "Technology Market" 2021

Ship EC-reducers JSC "Technology market 21.10.2022"

Ship EC-reducers JSC "Technology market 21.10.2022"

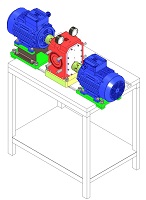

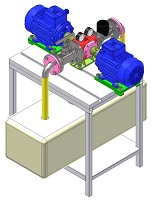

EC pumping unit for the main oil pipeline

EC pumping unit for the main oil pipeline

News

|

2024-03-28 |

| Comparative tests of a single-stage gearbox with a wheel made of high-strength structural polymer RIMamid have been carried out |

|

2023-12-18 |

| Negotiations were held on cooperation with Chinese companies and the supply of machines from China |

|

2023-12-15 |

| A meeting was held with the management of CAMZ. |

Archive

Projects

|

A pump with external EC engagement has been developed |

| General machine building |

|

A pump with internal EC engagement has been developed |

| General machine building |

|

The involute engagement pairs were replaced with EC |

| General machine building |

All projects