We offer for implementation the design solutions of CJSC "Technology Market"

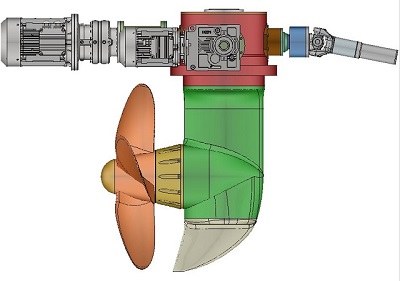

Vintorulovaya column

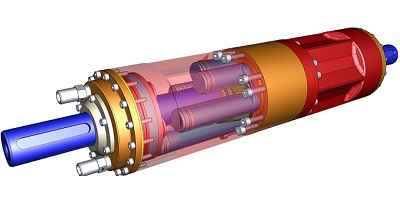

Hydraulic motor with integrated hydraulic distributor

Hydraulic motor (6+6 cylinders) with a built-in hydraulic distributor.

Advantages:

1. Low RPM (no gearbox needed, similar to the traditional hydraulic motor gearbox M)

2. High moment

3. Self-braking

4. Small size in height

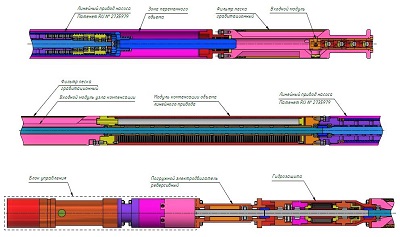

Submersible oil production pump for low-flow wells

Preliminary design of replacing a rod pumping unit with a submersible oil production pump for low-flow wells. The plunger is replaced by a pumping unit with a linear drive (patent RU No. 2735979), driven by a submersible electric motor.

Advantages:

1 Smaller overall dimensions of the pumping unit;

2 Easier commissioning of the installation;

3 The uptime is 2 years.

Characteristics:

1 Engine speed n=1000 rpm;

2 Piston stroke 300 mm;

3 Displacement of the piston 0.4 mm/rev;

4 Feed Q ≈1 m3/day;

5 Pump outer diameter 114-117 mm.

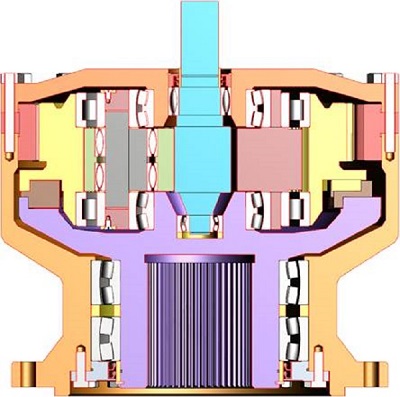

Planetary gearbox with pre-stage

Planetary gearbox with a preliminary stage (patents RU2677952 and RU2683896).

Gearbox Parameters:

- input power - 66 kW

- input speed - 600 rpm

The project was carried out within the framework of the program of import substitution of gearboxes for rolling metallurgical mills.

Advantages:

1. Fewer parts and bearings – increased reliability

2. Less weight by 40%

3. Smaller dimensions

4. Reduced manufacturing cost

5. The efficiency is 95%, against 90% of the prototype

6. Estimated durability – 50,000 hours

Manual winch

Pump with EC screws

The company CJSC "Technology Market" has developed and manufactured a pump with EC screws for the Ministry of Emergency Situations, based on an invention under a patent RU № 2534657 "Working body of a screw rotary machine". This pump has a high performance at high pressure(photo).

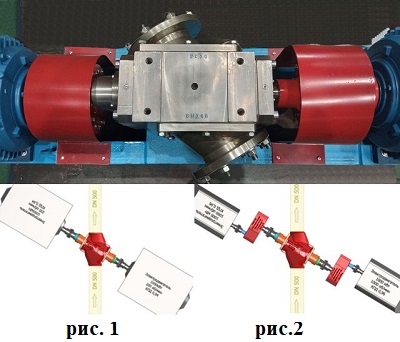

EC-pumping unit for the main oil pipeline

EC pump 200 rpm Rotor supports in rolling bearings 6.5 million tons per year, pressure 6.9 MPa

(рис. 1)

EFFICIENCY= pump efficiency* Engine efficiency= 0.92*0.94=0.85 Engine cost = 4.3 million rubles. X 2 pcs. Engine payback – 2 months No oil station costs, because rolling bearings are used in the engine and pump

(рис. 2)

Efficiency= Pump efficiency* Motor efficiency* Gearbox efficiency= 0,92*0,96*0,97 =0.86 Engine cost = 1.3 million rubles. X 2 pcs. Availability of gearbox maintenance costs

Comparison of an EC pump with a centrifugal one on the example of an oil trunk pipeline

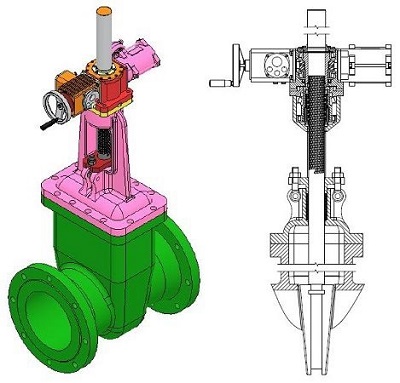

Linear reducer for wedge/gate valves

The design of a linear gearbox (patent RU2695742) for wedge/gate valves with cycloidal/sinusoidal thread on the spindle has been developed.

A single-stage conical (cylindrical) gearbox converts the rotational motion of the motor into the translational motion of the rod using a linear gearbox (pitch 0.5...0.75mm/rev) with an efficiency of 55%, rather than a standard nut with trapezoidal thread (pitch 8 mm/rev) and low efficiency = 20...30%.

The new design solution significantly increased the efficiency of the valve drive, which reduced the required engine power by 4 times and reduced the cost of the drive by ten times. The valve DU-300 with a pulling force on a rod of 15 tons is shown.

Such a linear gearbox has been successfully implemented as a tracking linear drive for opening/closing the flaps of a water tank for a fire helicopter of the Ministry of Emergency Situations with a force of 1.5 tons.

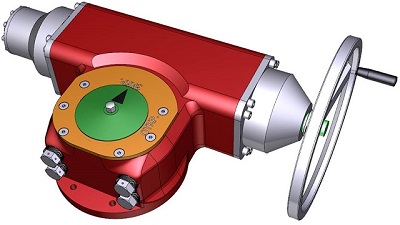

Manual ball valve drive with two-stage gearbox

Manual ball valve drive with two-stage gearbox:

- the first stage is a linear actuator based on the patent RU2695742 - 13.07.2018.

- the second stage is rack and pinion transmission with EC engagement. Landing F25 according to GOST 56001-2014. The angle of rotation of the output shaft is 90 ±5.

Hybrid Electric Bicycle Drive

The structure of the developed bicycle electric drive includes: an electric motor, a generator, a multiplier and a gearbox with a battery pack (scheme of the Prius hybrid car). Control is carried out from the connected device (smartphone) via bluetooth connection.

Modes set by bluetooth:

1. The driving mode is not due to the rotation of the pedals by the cyclist (the electric drive is disabled).

2. Mode of assistance to the cyclist by means of an electric drive.

3. Electric driving mode, without pedaling by the cyclist.

The advantages of the developed drive:

- Constant torque applied to the pedals at different speeds of the bike (when descending and ascending).

- During the descent, the batteries are recharged through a multiplier with a generator.

- When lifting, the electric motor is automatically turned on, driving the gearbox.