Upgraded gearbox with EC gearing ( General machine building )

Gearbox with EC-gear modernized.

Pluses:

1. The minimum number of steps is 2 (for prototypes 3), which increases the efficiency of the gearbox by (1-2%)

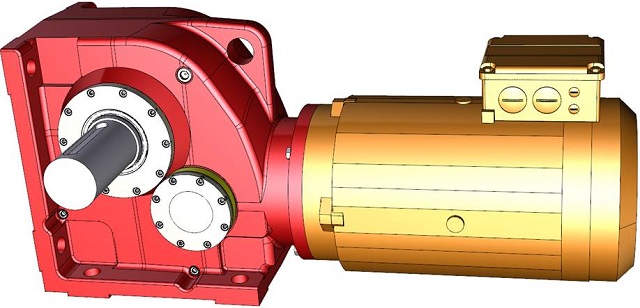

2. EC-gearing increases the transmitted moment by 30% compared with involute gearing. Or increases the durability of gear pairs.

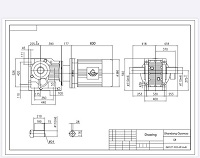

3. The minimum dimensions + minimum mass for the EC gearbox with the initial data of U-20.83 and 55 kW (1500 rpm) are obtained

4. The use of an electric motor with a hollow rotor made it possible to reduce the linear dimensions of the drive (by approximately 150 mm).

5. Based on the design of the EC-gearbox, a line-up similar to gearboxes can be created (different gear ratios, different powers)

6. The minimum cost in serial production (due to the reduced mass and small number of gears and bearings)

Rated torque: 7023 Hm. Gear ratio number: 20.8

Pluses:

1. The minimum number of steps is 2 (for prototypes 3), which increases the efficiency of the gearbox by (1-2%)

2. EC-gearing increases the transmitted moment by 30% compared with involute gearing. Or increases the durability of gear pairs.

3. The minimum dimensions + minimum mass for the EC gearbox with the initial data of U-20.83 and 55 kW (1500 rpm) are obtained

4. The use of an electric motor with a hollow rotor made it possible to reduce the linear dimensions of the drive (by approximately 150 mm).

5. Based on the design of the EC-gearbox, a line-up similar to gearboxes can be created (different gear ratios, different powers)

6. The minimum cost in serial production (due to the reduced mass and small number of gears and bearings)