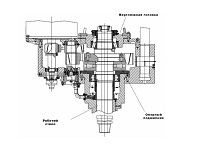

Top drive with EC-gearing ( Extraction and processing of raw materials )

The proposal to potential partners, investors and just interested parties

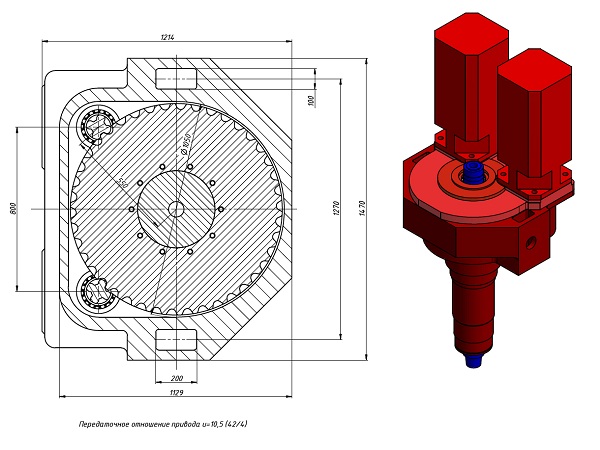

Our company has developed a promising solution to the use of EC-gearing in the Top gear drive for drilling rigs. This solution has several competitive advantages:

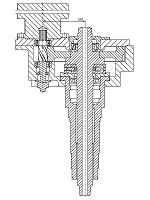

Reducing the number of stages in the gearbox from two to one, which will reduce the cost of gear and reduce the probability of a possible failure of the system;

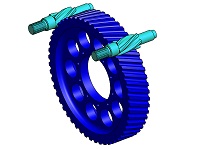

Increasing the thickness of the tooth will raise the overloading characteristics of the drive and increase the longevity of his work;

Reducing the axial dimensions of the drive will reduce the manufacturing cost of the drive as a whole;

EC-gearing requires a smaller amount of lubricant that will positively affect the performance at low temperatures;

The new tooth profile reduces losses within the drive.

Comparison with involute gearing