2019-03-30

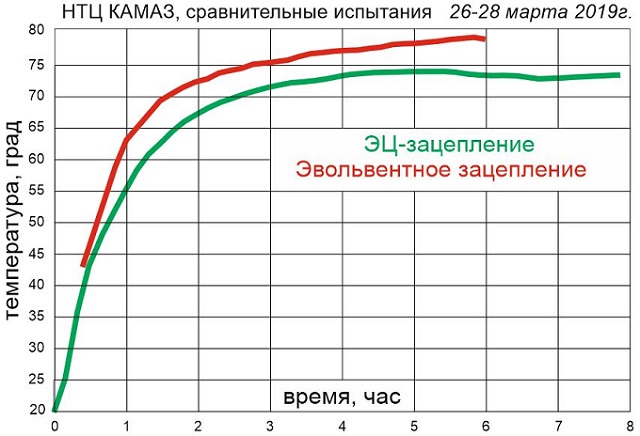

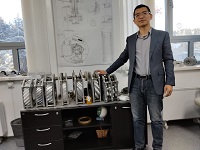

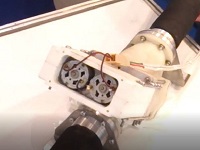

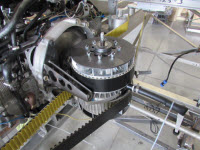

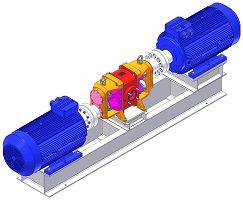

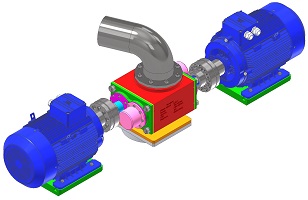

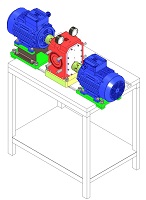

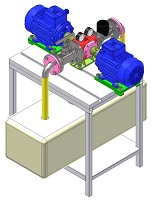

Since March 26, 2019, comparative tests of EC and involute gearing have been carried out at STC KAMAZ.

The test facility visited the gene. Director of KAMAZ PJSC - Sergey Kogogin.

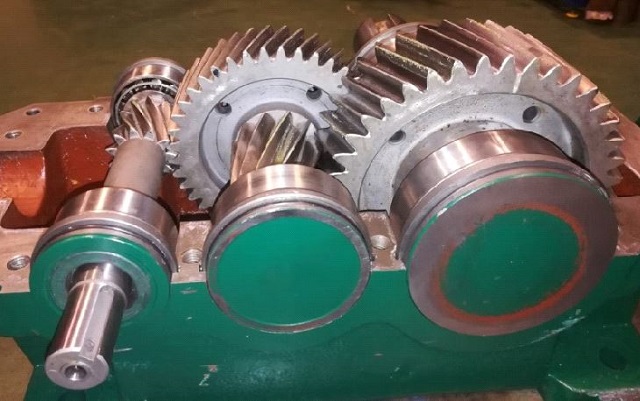

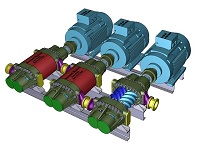

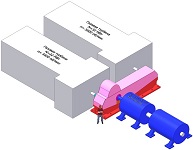

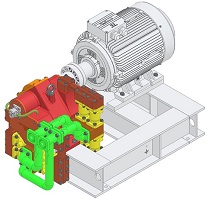

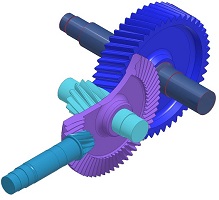

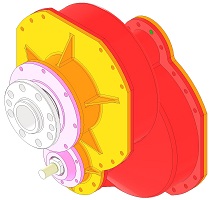

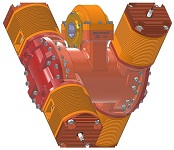

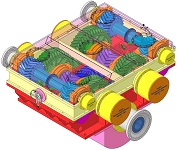

Two-stage helical gearboxes 5Ц2-125-12,5 with EC and involute gears participate in comparative tests.

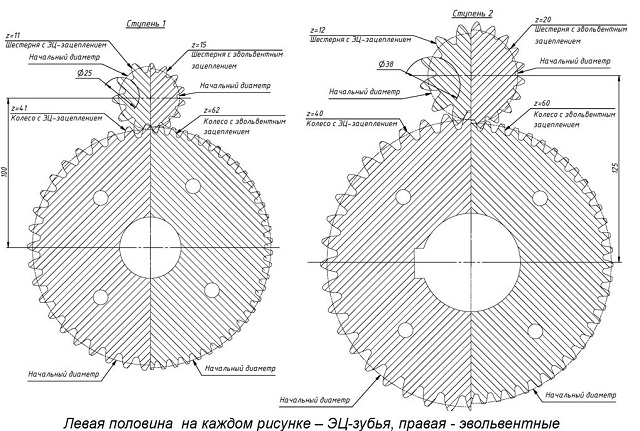

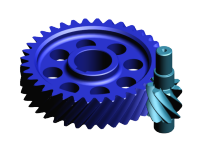

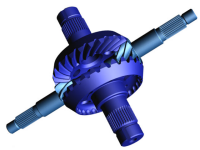

1. Involute gearing is processed by grinding (accuracy class 5-6). Z1 = 15/62, Z2 = 20/60. EC-gearing is processed by the method of blade processing (line-processing with a spherical carbide end milling cutter, 6-7 accuracy class). Z1 = 11/41, Z2 = 12/40.

2. Gear ratio: 12.5.

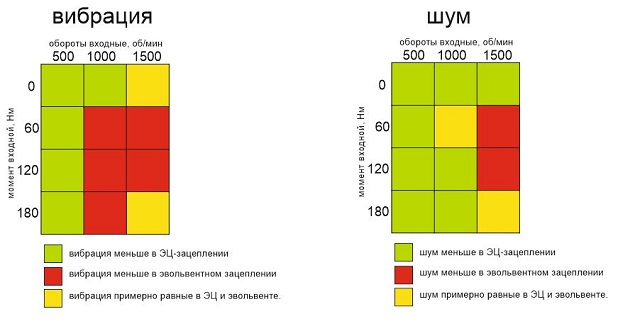

3. Input turns: 0-500-1000-1500 rpm.

4. Power: 30 kW.

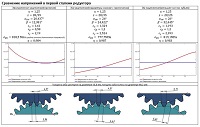

The results of comparative tests of EC and evolvent gears:

1. The oil temperature in the gearbox with EC-gearing is 5 degrees lower.

2. The efficiency in the EC-reducer is ~ 2% more.

3. Noise and vibration are approximately equal.

It was decided to continue testing for up to 80 hours using the methodology of STC KAMAZ. With an increase in the accuracy class of grinding of EC-teeth (5-6 class of accuracy) in EC-gearing, noise and vibration will be lower.

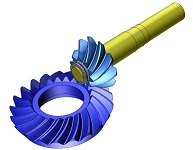

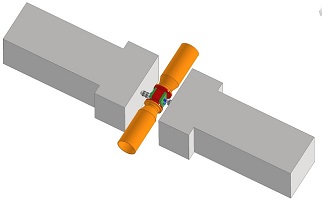

Comparison of involute gearing geometry and EC-gearing of a two-stage gearbox.

News

|

2024-04-19 |

| Expert opinion on the inclusion of ZAO Technologiya Market in the state register of small technology companies |

|

2024-03-28 |

| Comparative tests of a single-stage gearbox with a wheel made of high-strength structural polymer RIMamid have been carried out |

|

2023-12-18 |

| Negotiations were held on cooperation with Chinese companies and the supply of machines from China |

|

2023-12-15 |

| A meeting was held with the management of CAMZ. |

|

2023-11-28 |

| A meeting was held with the heads of JSC RUMO |

|

2023-11-26 |

| A meeting was held with the management of the TECHNOPOLIS Group of companies. |

|

2023-10-12 |

| The employees of CJSC "Technology Market" together with LLC "Technology Market" have developed and patented a promising design of a rocking machine gearbox |

|

2023-09-11 |

| A meeting with the Deputy General Director for Development of ITC AVTOTOR LLC took place in CJSC "Technology Market" Tomsk. |

|

2023-08-25 |

| A meeting was held with the technical management of Seversky Vodokanal JSC |

|

2023-08-16 |

| Mooring and sea trials of the ship's electrohydraulic crane on the sea tug "Captain Sergeev" of project 23470 have been completed |

|

2023-08-15 |

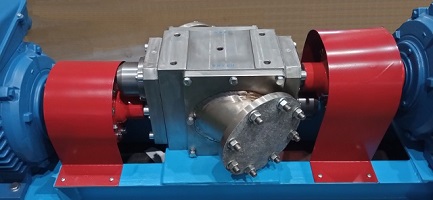

| The EC-gearing pump received a declaration of compliance with the requirements of the technical regulations of the Eurasian Economic Union |

|

2023-06-26 |

| Field tests of the EC-gearing pump, which has no analogues in the world, were conducted in Kuzbass. |

|

2023-05-31 |

| A meeting was held with Dmitry Borisovich Rozhkov, Head of the Administration of the Free Economic Zone Grodnoinvest of the Republic of Belarus |

|

2023-04-21 |

| A meeting was held with representatives of Rusnano on hydrogen topics (04.20.2023) |

|

2023-03-17 |

| On the territory of CJSC "Technology Market" (Tomsk), a meeting was held with the heads of the company "RUSNANO" |

|

2023-01-27 |

| A technical meeting with the heads of the leading shipbuilding enterprises of Russia took place on the territory of JSC TSKB "Iceberg" (St. Petersburg) |

|

2022-11-08 |

| Field tests of the EC-gearing pump were carried out. |

|

2022-10-18 |

| A meeting was held with the management of JSC “Techmashinnovation” |

|

2022-09-01 |

| «Капитан Найден» raised the St. Andrew's flag: the newest tugboat is included in the Black Sea Fleet |

|

2022-08-10 |

| On the tenth of August, a meeting was held with representatives of "Atommash" and "Romet" companies |

|

2022-07-11 |

| Comparative tests of septic tank compressors were carried out in the company CJSC "Technology Market". |

|

2022-02-01 |

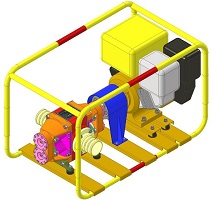

| The company CJSC "Technology Market" has developed and manufactured a pump for the Ministry of Emergency Situations. |

|

2021-12-17 |

| CJSC TECHNOLOGY MARKET was included in the "Rating of reliable partners" |

|

2021-12-10 |

| Developed a new model of a piston-free positive displacement machine (MOD) |

|

2021-07-26 |

| On July 26, a Zoom conference was held with the Chairman of the Skolkovo Foundation, Dvorkovich, Arkady Vladimirovich |

|

2021-07-22 |

| Our patented development at MAKS 2021 |

|

2021-07-01 |

| The technology of manufacturing cylindrical and conical chevron EC-gearing has been worked out |

|

2021-05-18 |

| The use of the EC-Pump will reduce the cost of oil pumping by 10%. |

|

2021-03-19 |

| On the territory of JSC "KONAR" a meeting was held on the joint development of technologies of new air propellers |

|

2020-12-03 |

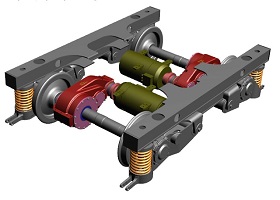

| Modernization of the gearbox 029.00.00.000 РЭ ofthe railway locomotive (made in Ukraine) based on EC-gearing |

|

2020-12-03 |

| Models of three new linear gearboxes were developed and manufactured. |

|

2020-10-05 |

| Published a new video of testing the Russian drone-trucker BRAERON, with a gearbox with EC-gearing |

|

2020-09-24 |

| Employees of ZAO TM visited PNPPK with a working visit. |

|

2020-09-22 |

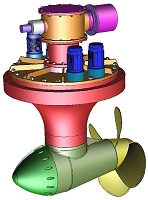

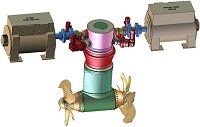

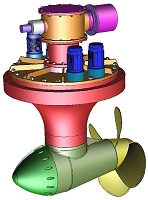

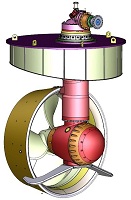

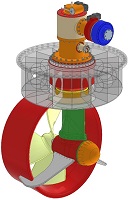

| Patent No. 2731811 for a rudder propeller of increased strength was received, which can be installed on an Arctic platform as a VRK-3.5 MW Arc-8. |

|

2020-09-18 |

| The magazine "Shipbuilding" No. 4-2020 published an article by employees of the company "Technology Market": V. Stanovskoy, O. Tsyganov, E. Karpenko. Domestic rudder drive. |

|

2020-09-18 |

| A new section "EC Models" has been created on the site for acquaintance with EC-gearing. |

|

2020-09-17 |

| The Tekhnologiya market CJSC company has developed a layout of a linear reducer with intermediate rolling elements (balls) and a cycloidal shaft profile. |

|

2020-08-12 |

| Demonstration of the operation of the layout of the Rotary Support Device (OCP) to the Customer |

|

2020-08-12 |

| Published a new video of testing the Russian drone-trucker BRAERON, with a gearbox with EC-gearing |

|

2020-08-06 |

| Technology Market CJSC has granted a license to SDK LLC for the right to use EC-gearing in ship equipment. |

|

2020-08-06 |

| The customer launched a series of a linear actuator with a force of 1500 kg (developed by JSC "Technology Market"). |

|

2020-07-29 |

| In Tomsk, a meeting was held with the Director of PJSC PNPPK (Perm). |

|

2020-07-02 |

| By the order of LLC “Mechanika-R” (St. Petersburg), the VRK-10 MVT (2x5 MW) was developed |

|

2020-07-02 |

| By order of LLC “Mechanika-R”, a VRK-3.5 MW Arc-8 was designed |

|

2020-06-08 |

| The Tekhnologiya Market CJSC company has developed a model of a linear gearbox with intermediate rolling elements (balls) and a sinusoidal shaft profile. |

|

2020-04-23 |

| The LLC "EC-Pump" company made the submersible pump with an EC profile of a screw surface. |

|

2020-03-20 |

| In the Design Bureau "Aviaresheniya" was another demonstration of a heavy drone with EC-gear. |

|

2020-03-17 |

| The report of the company "Technology Market" CJSC was published in the proceedings of the conference "Modern Problems of Mechanical Engineering 2019" |

|

2020-02-12 |

| In Tomsk, a meeting was held with the technical director of RUDGORMASH, Yuri Anatolyevich Grishin |

|

2020-02-02 |

| STC PJSC Kamaz has sent a protocol for comparative tests of EC and Involute gearing in the gearbox 5Ts2. |

|

2020-01-22 |

| There was a meeting with experts from the KONAR Industrial Group. |

|

2019-12-20 |

| The first water-jet with a bevel gearbox with EC gears was manufactured |

|

2019-12-06 |

| The tugboat for the Navy "Captain Naiden" was launched |

|

2019-11-25 |

| Director of the company Technology Market took part in the fifth interdepartmental scientific and practical conference of the Ministry of Defense of the Russian Federation. |

|

2019-11-13 |

| A vessel with installed VRK-2500 (with EC-gearing) is ready for launching. |

|

2019-10-24 |

| The presentation of the development of Technology Market CJSC by Dr. Mafred Liebl took place. |

|

2019-09-20 |

| In Yaroslavl, the ship is equipped with one of two VRK-2500 with EC gearing. |

|

2019-08-28 |

| B2B negotiations with entrepreneurs from Vietnam took place in Tomsk CCI |

|

2019-07-23 |

| 07.22.2019 "Konar" shipped VRK-2500 to Yaroslavl for installation on the ship. |

|

2019-07-18 |

| Conducted another test layout EC-pump. |

|

2019-07-03 |

| Conical EC-transmissions manufactured by Technology Market were installed in the customer’s products. |

|

2019-06-07 |

| In Moscow at the exhibition of the Ministry of Emergency Situations there was a demonstration of the Multiphase pump with screws with EC meshing. |

|

2019-06-05 |

| The final stage of the assembly of the propeller-steering column with EC-engagement VRK-2500 has begun at the KONAR JSC. |

|

2019-04-19 |

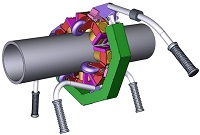

| According to the technical task of the oil service company, a thickness gauge was developed and manufactured. |

|

2019-04-18 |

| A contract was signed with KAMAZ for the development of gearboxes with EC-gearing for KAMAZ vehicles |

|

2019-04-15 |

| The patent of the Russian Federation for the invention "The mechanism of transfer of rotation between parallel shafts". |

|

2019-04-13 |

| In the AO KONAR (Chelyabinsk) started the assembly of propeller-steering speakers VRK-2500. |

|

2019-04-11 |

| On April 11, comparative tests for the development of a two-stage spur gear 5TS2-125-12,5 with involute and EC-gears were completed. |

|

2019-03-30 |

| Comparative tests of EC and involute gears in a two-stage cylindrical gearbox are carried out at the STC KAMAZ. |

|

2018-12-06 |

| A meeting was held with the technical specialists of STC "KAMAZ" |

|

2018-06-14 |

| Meeting at the Scientific and Technical Center "KAMAZ" |

|

2018-05-29 |

| Director of CJSC "Technology Market" held a presentation for the delegation from Tatarstan. |

|

2018-05-22 |

| At the KEMZ, a hypoid electric drive was manufactured for the Electro-Mechanical booster of the VAZ car. |

|

2018-05-17 |

| Company CJSС Technology Market held a presentation of its projects for JSC "TVEL". |

|

2018-05-04 |

| With the help of a 3D printer, a model sample of nut - screw transmission (NST) |

|

2018-04-06 |

| A linear transmission of a new design was developed. |

|

2018-03-06 |

| The jagged conical pairs with EC-gearing for the rotor column "VRK-400" have been developed. |

|

2018-02-01 |

| The results of testing within the framework of the advance project of the Perspective Research Foundation at the Krylov State Research Center |

|

2018-01-29 |

| Within the framework of the advance project of the Perspective Investigations Fund, two gearboxes have been compared. |

|

2018-01-17 |

| A new patent has been obtained. |

|

2017-12-19 |

| A meeting was held with the technical director of the PAO PNPPK Ryaposov V.A. |

|

2017-12-12 |

| The customer-manufacturer tests three-stage gearbox with EC-gearing. |

|

2017-11-30 |

| The news about the screw-column developed in our company was posted on two Internet resources. |

|

2017-11-14 |

| In the reducer of the VTT-22T1 carloader, the evolvent gears of the second stage were replaced by the EC-gears. |

|

2017-09-23 |

| The next shipment to the Kuzbass of the main transmission with EC-gearing for BELAZ-7555 |

|

2017-09-22 |

| At the NEVA-2017 exhibition the development of the Vinto-Helm-Steering Column VRK-2500 kW with EC-reducers was presented. |

|

2017-08-17 |

| By the method of investment casting, a batch of EC wheels and a gear shaft have been manufactured. |

|

2017-05-19 |

| At the exhibition "Metalworking - 2017" (Moscow) the general director of "Technology Market" CJSC Victor Stanovskoy held a number of business meetings. |

|

2017-03-23 |

| In the city of Tomsk and the town of Yurga (Kemerovo region), meetings were held on the development of products for shipbuilding. |

|

2017-02-27 |

| A set of design documentation "conical pair with EC-gearing to 660 kW" |

|

2017-01-24 |

| There was a board of Mechanical Engineering of the Kemerovo region. |

|

2017-01-12 |

| The visit of the delegation of OOO "Mehanika-R" |

|

2016-12-16 |

| There was a visit to the management of JSC "LGM" CJSC "TM" |

|

2016-11-30 |

| EC-gearing presented the governor of the Kemerovo region |

|

2016-11-25 |

| Obtained a new patent |

|

2016-10-28 |

| EC technology was presented to Dmitry Rogozin |

|

2016-10-24 |

| Familiarity with EC-gearing |

|

2016-09-20 |

| Prepared for delivery to the customer with plastic and steel wheel EC-reducer. |

|

2016-08-04 |

| A meeting with a representative of the company to determine VOLLMERs equipment for the manufacture of profile tools for cutting teeth EC-gearing. |

|

2016-07-27 |

| In the department of Machine Tool Industry and Trade Ministry held a meeting on implementation of EC-gearing. |

|

2016-06-09 |

| Negotiations with enterprise ZAREM about the cooperation in the area of EC-Gearing took place on the exhibition Coal 2016 in Novokusnezk. |

|

2016-06-08 |

| The 100 best inventions of Russia in 2015. |

|

2016-05-25 |

| The exhibition Engineering-2016 |

|

2016-05-20 |

| A meeting about EC-Gearing took place with KAMAZ |

|

2016-04-25 |

| New projects with EC-Gearing for maximum power transmission |

|

2016-04-18 |

| Delegation SEW-Eurodrive (Germany) has visited our enterprise |

|

2016-03-10 |

| Hypoide gear with EC-teeth for BMW car has made |

|

2016-02-24 |

| Company CJSC TM visited General and Technical Director of the Kaluga Electromechanical Plant |

|

2016-02-17 |

| The visit of the director of the company Gleason |

|

2015-12-31 |

| С Новым годом и Рождеством! |

|

2015-12-24 |

| ЗАО ТМ - номинант конкурса "Приоритет-2015" |

|

2015-12-07 |

| Zahnstange mit EZ-Verzahnung |

|

2015-11-30 |

| Treibwerk-Erprobung des Hubschraubers Afalina |

|

2015-11-15 |

| Erprobungen einer Helikopter-Drohne |

|

2015-08-05 |

| The EC-Gearing for Bosch-Company is presented |

|

2015-07-08 |

| Following the invitation of BMW Forschung und Technik GmbH (Munich) the EC-Gearing was presented. |

|

2015-06-27 |

| The presentation of EC-Gearing for Henschel Аntriebstechnik |

|

2015-05-21 |

| The firm HeliWhale presented AFALINA high-speed helicopter |

|

2015-04-17 |

| Report about Hannover exhibition, 13-17 Apr. 2015 industrie automation. |

|

2015-03-20 |

| Hannofer Fair Germany 13-17 April 2015 |

|

2014-12-19 |

| Development of EC-gearing became the winner in the first open competition of civil innovative projects of the OPK organization of Russia. |

|

2014-11-11 |

| Bench tests have been passed successful |

|

2014-10-20 |

| The use of modern materials for EC-gearing. |

|

2014-10-10 |

| Made the first planetary gearbox with EC-gearing. |

|

2014-08-01 |

| Проведены испытания макета гидротурбины нового образца (ЭЦ-гидротурбина). |

|

2013-11-20 |

| Bevel gearbox "Tandler" were upgraded. |

|

2013-11-01 |

| The EC-gearing were presented on the Open Innovations Forum held in Moscow. |

|

2013-10-29 |

| The delegation from Tomsk Chamber of Commerce visited the three largest companies in Krasnoyarsk. |

|

2013-10-21 |

| The metal cutting technology with profiled end tool was tested for EC-wheel production. |

|

2013-10-04 |

| X International exhibition of high-technology and weaponry – Russia, Omsk 2013 |

|

2013-08-20 |

| CJSC «Technology Market» took part in an exhibition devoted to the Day of the innovation Ministry of the Russia Defense. |

|

2013-08-19 |

| Took place meeting with the Deputy Chairman of the State Duma Sergei V. Zheleznyak. |

|

2013-08-13 |

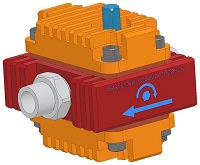

| Successfully tested hand drive for valves. |

|

2013-07-18 |

| For comparative testing of cylindrical gear wheels with EС-gearing is made and put into operation a test stand. |

|

2013-07-14 |

| The test of double screw submersible pump based on EC-gearing was successfully passed. |

|

2013-06-18 |

| CJSC "TM" developed and tested screw, multi-phase EC-pump. |

|

2013-05-17 |

| The annual scientific conference «VOITH» (Germany, Crailsheim) took place. A report about EC-gearing has been presented successfully. |

|

2013-01-31 |

| The agreement with IZ-KARTEX named after P.G. Korobkov Ltd. about the drives of heavy excavation equipment was reaches. |

|

2012-12-12 |

| The new license for production a multiplier with EC-gearing sold. |

|

2012-10-10 |

| The test gear gone |

|

2012-07-20 |

| Designed and constructed a new generation of planetary module |

|

2012-07-19 |

| Shipment of the next batch of EC-gearing wheels |

|

2012-05-29 |

| International patent is obtained |

|

2012-05-22 |

| The governor is visited the «Technology Market» company |

Projects

|

The NC-900 coal-fired EC pump has been developed |

| Extraction and processing of raw materials |

|

A tanker cargo pump has been developed. |

| Extraction and processing of raw materials |

|

A promising design of the EC turbocharger has been developed |

| Extraction and processing of raw materials |

|

A summing turbo reducer of 64MW has been developed |

| Extraction and processing of raw materials |

|

A plunger-free piston pump has been developed |

| General machine building |

|

A pump with external EC engagement has been developed |

| General machine building |

|

A pump with internal EC engagement has been developed |

| General machine building |

|

The involute engagement pairs were replaced with EC |

| General machine building |

|

A bellows valve actuator with a force of 5.3kN has been developed |

| Extraction and processing of raw materials |

|

The VRK-750 project has been developed |

| Transport |

|

The EC-reducer of the railway trolley has been developed |

| Transport |

|

Comparison of radial sections of teeth of involute and EC engagement |

| General machine building |

|

A manual quarter-turn valve actuator has been developed |

| Extraction and processing of raw materials |

|

A two-stroke engine for an aircraft has been developed on the basis of a rotary-motor converter (BP) |

| Transport |

|

The design of the gearbox of a single-engine aircraft has been developed |

| Transport |

|

A universal block of a rodless converter (BBP) of linear motion into rotational motion has been deve |

| General machine building |

|

EC-motor pump has been developed |

| General machine building |

|

At the request of the customer, a comparison of engagement was carried out |

| General machine building |

|

A vacuum sampler has been developed |

| General machine building |

|

The ship's summing gear has been developed |

| Transport |

All projects